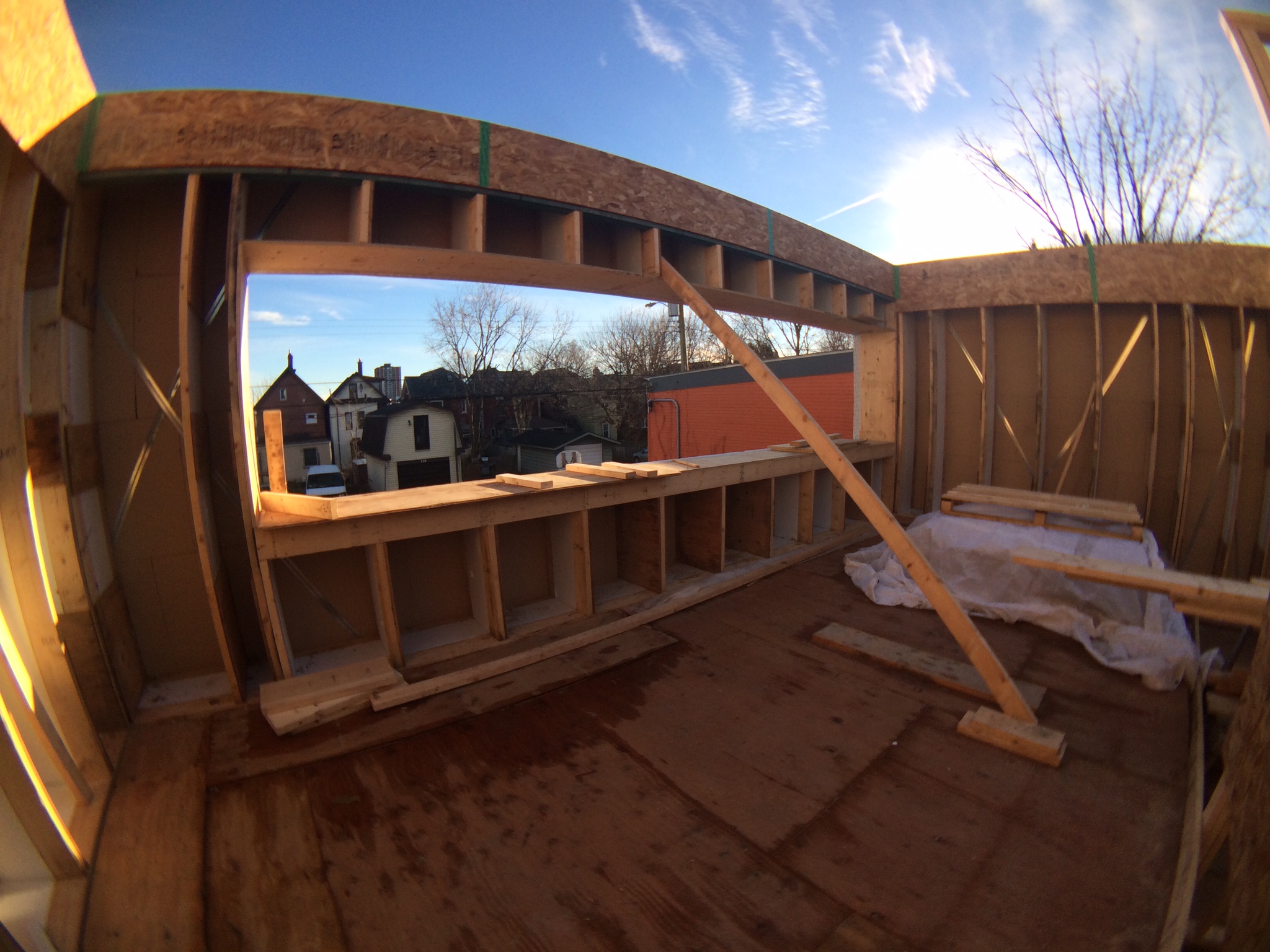

With the wood framed walls well underway now, I thought it was high time that I sat down to write a post about the design and theory behind the wall system we are using. When we set out to build our project, I spent a lot of time thinking about double stud wall construction. For those unfamiliar, a double stud wall is a wall made up of two seperately framed walls, one inside of the other, usually seperated by a space for insulation. The beauty of the double stud wall is that the overall thickness of the wall is very flexible: by moving the two stud walls further apart you can add insulation and increase the effective R-value of the whole assembly. The continuous insulation is also a great thermal break preventing thermal bridging through studs.

Still, there are a couple of challenges that the traditional double stud wall presents. First of all, the exterior wall is usually built first, and the interior wall much later once the house is enclosed. The main drawback of this is that the exterior wall necessarily becomes the load bearing structural wall. I'm a big fan of keeping structure as much to the inside of the thermal envelope as possible for two reasons: first, it keeps the structural elements warm and dry and protected from cycles of expansion and contraction, and second, it reduces the number of structural penetrations or complex structural details that interfere with a good air barrier.

When designing the system for our project, I set some key goals for myself. I wanted to have a system that hit all of these key points:

- Structure to the interior

As discussed above, this is just the right place for structure to be. It also facilitates the next point below...

- Air barrier to the interior, and as straight and uninterrupted as possible

I wanted to use OSB with taped joints for the primary air barrier. In order to keep from having a messy transition at floors, the idea was to come up with a way to run the air barrier up straight past the floors without joist cavities to contend with

- Excellent drying potential

With all walls, and especially with high R-value walls, it is crucial that the wall has good drying potential, and that no opportunities for condensation are created within the assembly.

- High R-value (obviously!)

This could have been the first point. Super-insulated is Passive House's alternate code name.

- Can be insulated from the interior after framing is complete using mineral wool batts

I wanted to avoid insulation that would require scaffolding or lifts for installation, partly because of the limitations of the site, and partly for cost and labour savings. In terms of insulation type, I'm a big fan of mineral wool insulation. What's not to love? It's water resistant, mould-proof, fire-proof, high in recycled content, and has a good R-value that actually improves as it gets colder outside.