2. No external ducting

Here’s where our list of options gets dramatically reduced. With our house, we are not venting to the outside (heaven forbid we penetrate the air barrier). As a result, we must find recirculating options for appliances that otherwise would (vent to the outside), such as the range hood ventilator and our clothes dryer. Oh, and since we have no external ventilation, this precludes us from considering a gas cooktop because open flames without external ventilation is a ‘no-no’ for building code.

At first these may sound like Passive House trade-offs, but in fact, Mark and I are seeing them more as ‘trade-ups’. Because why would you want to throw all that warm air (aka. Heat, aka. Energy) out of the house when you could recycle it and feed the energy needs of our house from within rather than pull from the grid? I sure wouldn’t.

With that in mind, here’s what we decided to go with:

Dryer

Whirlpool 7.3 cu ft. HybridCare™ Ventless Duet® Dryer with Heat Pump Technology

The most efficient dryer on the market also happens to use ventless heat pump technology. The same heat pump technology that operates our domestic hot water tank. Bam.

Washer

We’re simply getting the matching Whirlpool washing machine.

Dishwasher

Bosch 500 series - SHP65T52UC

Bosch dishwashers also use heat pump technology, making them pretty darn efficient. This one is whisper quiet, which we like, especially considering our main floor is rather open-plan.

Cooktop

Bosch 500 Series 30” Induction Cooktop

We are so excited that induction technology has made it to the consumer world! There are so many great things to say about induction. It uses magnetic conduction, which is instant, consistent, precise and significantly more energy-efficient than ol’ thermal conducting cooktops (gas and electric) which throw away much of the heat they produce. And best of all, you can put your hand on the burner immediately after taking the pot away. Who hasn’t wanted to do that before?! Well now you can.

Wall oven

Whirlpool convection 30” white - WOS 92EC0AS

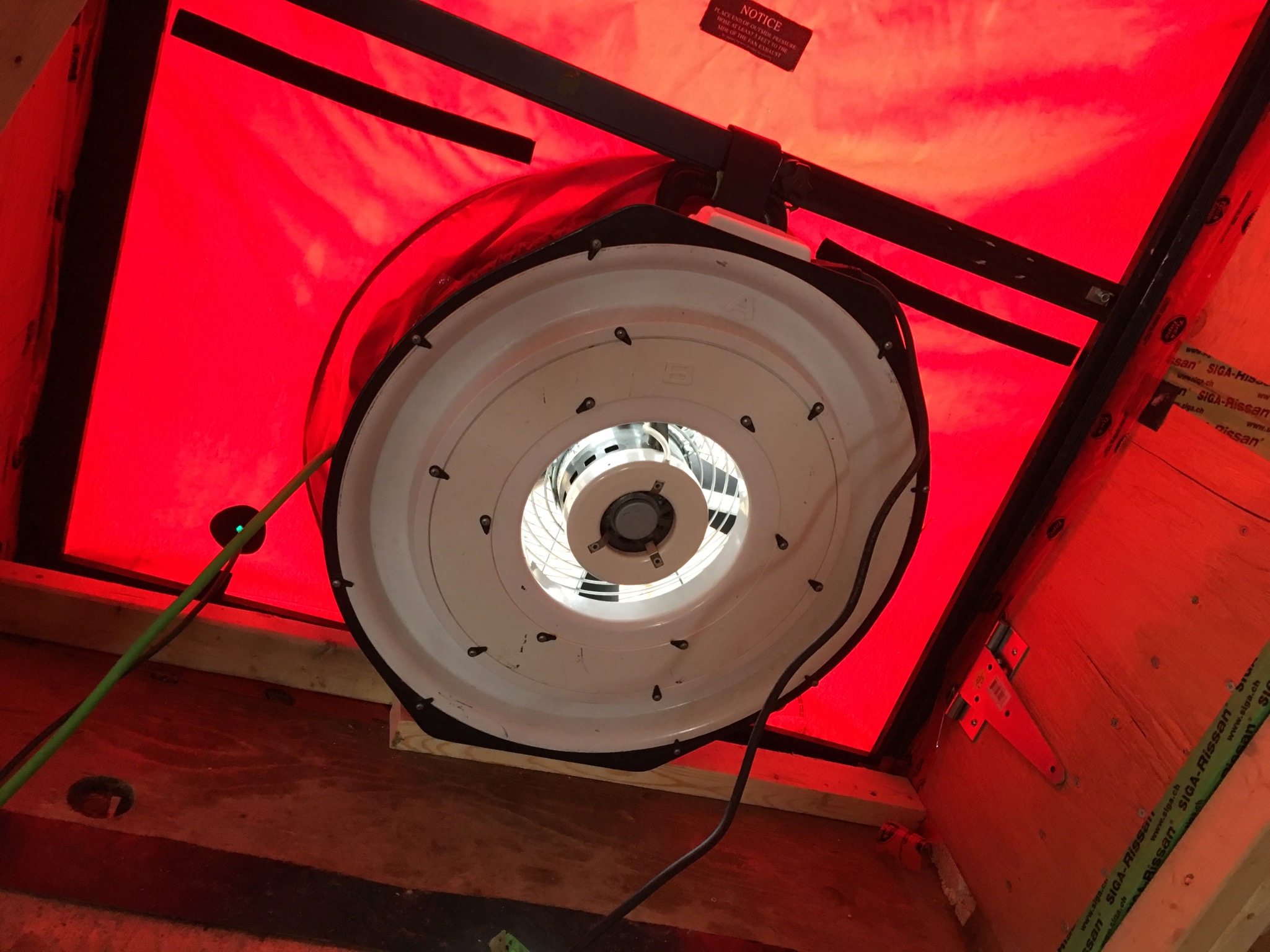

Ventilation

Best Cattura Downdraft 30” - D49M30SB

This was by far our most complicated appliance to figure out. Our cooktop is in the island — we like to cook and be part of the action. We have a very large, very beautiful window spanning the length of our kitchen. The last thing we wanted to do was to put a space-aged, over-the-island range hood hanging down from the ceiling, disrupting our lines and views out the window. In order to avoid this, we needed to find a downdraft ventilator — one that sits in the island itself — with a recirculating kit.

Downdraft ventilators are widely regarded as inferior to mounted-above styles because they aren’t able to catch as much of the steam, smoke, and heat, that naturally rises. Even though downdrafts are not quite as effective at removing air, this is less of an issue for us thanks to our induction cooktop. A gas cooktop uses combustion to heat, a natural byproduct of which is smoke (which is why you’re required to vent to the outside with a gas cooktop). With induction, smoke and other pollutants are only a byproduct of forgetting the pot of boiling pasta on the stove too long, which reduces the number of contaminants our blower has to extract from the air. For the most part, our ventilator will only have to remove steam and smells. Any pollutants will be cleared, prior to recirculation, with a charcoal filter.

There are several companies that make these downdraft ventilators, with recirculation kits, that actually pop-up out of the counter to heights as high as 18”. They are all luxury brands. I’ve had a hard time coming to terms with the fact that our downdraft vent, which is inferior to overhead vents, was going to cost as much as the cooktop and wall oven combined. This is one case where design has trumped all other options.

On the ‘up’ side, however, we can take advantage of the recirculated air and improve the overall experience of working in our kitchen. How, you ask?

We will be mounting the fan blower and charcoal filter in our mechanical room, effectively removing any noise from the kitchen itself. No more shouting over a noisy fan motor. And by moving the warm cooking air into the mechanical room, we will be augmenting the energy source for our domestic hot water heater. Our domestic hot water tank is a heat pump model, which pulls heat in from the surrounding air through a compressor and into our water. The surrounding air (in our mechanical room) becomes slightly cooler as a result. Our downdraft air supply will help make-up some of that heat lost to the hot water tank, and reduce our requirement to pull from the grid.

Make sense? I’m not surprised if it doesn’t. I’ll be posting a video of Mark explaining this to me with helpful diagrams likely tomorrow....

So there you have it. Some big decisions made. Each decision turns out to be more of an ordeal then at first glance. I know more about dishwashers now than I ever thought I needed to know. But I'm glad I took the time to do the research and understand. As we are doing with every aspect of our build.

I should also note that we purchased a Consumer Reports Online subscription for the duration of the build to help us with some of our research. It’s been most helpful so far in choosing our appliances. http://www.consumerreports.org/